The SQ-10 & SQ-30 Laser Coding Systems

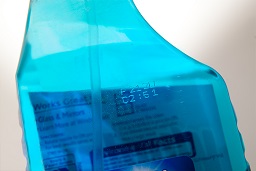

Squid Ink’s SQ-10 and SQ-30 laser coding systems are designed for high speed food and beverage, pharmaceutical, cosmetic, and other primary coding applications. Squid Ink lasers can permanently mark onto paper, cardboard, plastic, glass, wood, coated metal, leather, and more. Users select between a 10W (SQ-10) and 30W system (SQ-30) depending on their specific application requirements.

Application Versatility

- Permanent coding of text, time and date, bar codes,

serial numbering and more - Quick and easy installation for both stationary and moving products

- Easily fits into production environments where space is limited

- Laser head can be rotated 90° in less than 5 minutes

Reliable & Economical

- No ink/consumables for lower cost of ownership

- Clean and eco-friendly coding system

- Rugged cast aluminum controller body

- IP54 rating ensures maximum reliability and uptime in demanding applications

- Integrated key switch and interlock relay for increased safety on the production floor

BENEFITS OF THE SQ-LASER

- CO2 marking systems

- 10W and 30W models

- Static or continuous marking modes

- No inks or solvents – environmentally friendly and cost-effective

- Marks on plastic, glass, metals, paper, chipboard, building products, foils, and more

SYSTEM SPECIFICATIONS

- Print Technology – CO2 laser coding system, full sealed RF-excited metal tube

- Laser Wavelength – 10.6μm

- Laser Galvanometer – High-precision 2D high-speed scanning galvanometers

- Cooling Method – Atmospheric air-cooled

- Dust Way – Sealed

- Power Consumption – 500W – 1000W (110VAC, 60Hz)

- Marking Focal Length – 100mm – 190mm (133mm currently on SQ-10 & SQ-30)

- Position Accuracy– 0.01mm

- Minimum Line Width – 0.1mm

- Marking Area – 50mm X 50mm – 175mm X 175mm

- Assembly Line Speed Support – <120m/min

- Marking Speed – 800 – 1000 characters/second

- Character Size – Adjustable in marking range

- Marking Line Number – Code Rotation – 0 to 360°

- Software Features – Counter, lot counter, shift code, time and date, expiration date

- Operating Languages – English and Chinese

- Cabinet Construction – Heavy duty cast aluminum

- SQ-10 Cabinet Dimensions – 29” (74cm) L x 6.25” (16cm) W x 7.25” (19cm) H

- SQ-30 Cabinet Dimensions – 29” (74cm) L x 5.375” (14cm) W x 7.5” (19cm) H

- SQ-30 Power Controller Dimension – 13” (33cm) L x 5.5” (14cm) W x 10.25” (26cm) H

- Electrical Requirements – 90 – 240 VAC, 50/60Hz

- Operating Environment – 40°F – 105°F (5°C – 40°C)

- Humidity Range – 10 – 90% relative humidity, non-condensing

- Packaged Weight – SQ-10: 56 lbs. (25kg); SQ-30: 67 lbs. (30kg)

OPTIONAL ACCESSORIES

- Print Trigger – Optical, fiber optic, ultrasonic, laser, metal proximity, capacitive proximity

- Encoder – For operation with variable speed conveyors

- Mobile Stands – Heavy duty stand with ability to rotate laser controller in any direction and easily raise and lower marking machine by a single operator; includes casters for easy transportation within plant

- Installation and Training – On-site installation and training available