An Ideal Solution for Produce Packing

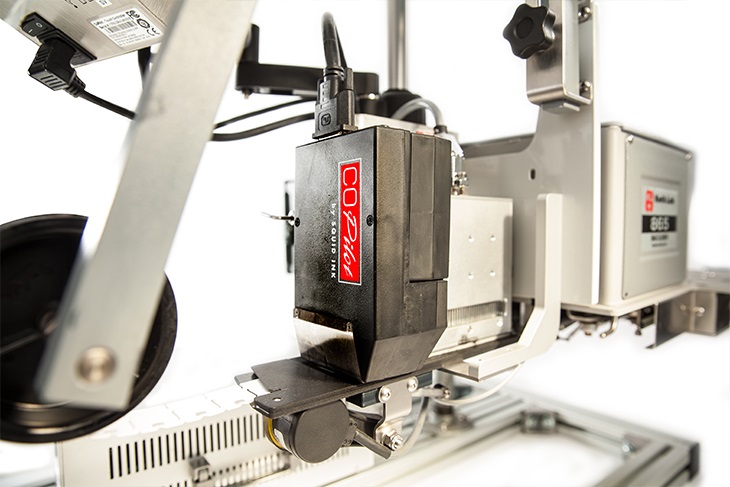

The 905 Series CoPilot UV LED Curing System integrated with Kwik Lok’s 865 Automatic Bag Closing Machine provides an ideal solution for produce packers printing sell by dates, suggested list prices, 2D bar codes, and more on fresh produce bag closures.

Make a Mark That Lasts

maintenance ink cured only by UV LED light. The ink won’t dry until it comes in contact with the UV light, meaning a lower maintenance solution than all other ink jet technologies. This instant LED curing ink leaves a permanent mark that is impervious to environmental factors such as sunlight, water, moisture, temperature, and contains virtually no VOCs, making it ideal for food applications. Additionally, the 905 Series CoPilot system utilizes easy-to-use software modified specifically for the produce industry for easy message programming and recall.

Out With the Old, In With the New

UV LED technology offers several advantages over existing TTO (thermal transfer overprint) systems currently used in produce applications. Squid Ink’s 905 Series CoPilot system does not require compressed air, making it an easy install anywhere in the plant, or in the field. In addition, the 905 system offers 20-25 times fewer ink/ribbon changes, and up to 5 times lower cost per print. Typical cost per print is 20 cents per 1,000 loks. Add in a longer printhead life span and no work stoppages for ribbon breaks, and users will enjoy increased savings on their initial and ongoing operating costs.

Designed for Durability

Squid Ink’s 905 Series CoPilot UV LED Curing System is designed to meet the demands of your application. You can be confident that the 905 CoPilot’s rugged design will withstand your produce packaging environment while providing superior quality print and UV curing. For ease of integration, the 905 Series mounts directly to Kwik Lok’s 865 Closure Machine and requires no need for preheating or compressed air. The 905 UV LED system can be programmed to run in manual, semi-automatic, or automatic mode to match the operation of your manufacturing line. For quick start-ups, 905’s fast response functionality means that the system can be powered on and ready to go at an instant, eliminating downtime and increasing your ROI.

PRINTING SYSTEM SPECIFICATIONS

- Print Technology – Piezo impulse printhead technology

- Maximum Print Height – 0.7” (1.8 cm)

- Vertical Print Resolution – 185 dpi

- Horizontal Print Resolution – 205 dpi

- Print Speed – Up to 135 feet/min. (41 m/min.) @ 205 dpi

- Time & Date – Internal real time clock with battery back-up

- Product Sensor – External print trigger

- Communication Interface – One USB host and one Ethernet input

- Touchscreen – 4.3” (10.9 cm) full color touchscreen display

- Ink Cartridge Volume – 200ml

- Low Ink Indicator – Message alert on touchscreen; LED light beacon optional

- Electrical Requirements – 100 – 240 VAC, 50/60 Hz

- Operating Environment – 34°F – 104°F (1° – 40°C)

- Storage Environment – 0°F – 140°F (-18° – 60°C)

- Agency Certifications – CE and TUV certified

COPILOT SOFTWARE SPECIFICATIONS

- Time & Date – Multiple formats including: 1,2,4-digit year, 1,2-digit month, 3-letter month, custom month string, 1-letter day of month, 2-digit day of month, 1-digit day of week, 1,3-letter day of week, 2-digit week of year, 3-digit Julian year, 1-letter hour (a-x), 2-digit hour (12 or 24), 2-digit minute, 2-digit second, 1,2-letter meridian (A/P, AM/PM) custom week string

- Item Numbering – Sixteen counters, one of which can be a daily counter

- Shift Codes – Four programmable shift codes with automatic rollover

- Bar Codes – Code 39, Interleaved 2 of 5, UPC-A, EAN-8, EAN-13, Code 128, UCC-128, SCC-14 ITF, SCC-14 128, SSCC-18, MSI, DataMatrix, QR, and PDF417 bar codes standard dynamic. Other barcodes can be printed as static bitmaps.

- Fonts – Arial, Arial Bold, Courier, Tahoma Bold and Lucida resident fonts for use in variable data elements. Static elements in any Windows® font

- Logos – Most image files supported with Orion Graphical Interface Software

- Printing Features – Reverse, invert, rotate, repeat

- Number of Messages – 1GB storage space will store approximately 1000+ messages

- Ink Usage – Shown in Orion™ PC Software, per message format

UV LED SYSTEM SPECIFICATIONS

- Wave Length – 395 +/- 5nm

- Controller Dimensions – 13” x 9” x 5.2” (33cm x 7cm x 13cm)

- Illuminating Head Dimensions – 4.7” x 2.6” x 4.7” (12cm x 7cm x 12cm)

- Illuminant Output Control – 10% – 100%

- Power Supply – 90 – 220 VAC, 50/60 Hz, 300W

- LED Lifetime – 20,000 hours or more

- Operating Environment – 14°F – 131°F (-10° – 55°C)

- Storage Environment – 13°F – 185°F (-10° – 85°C)

COPILOT OPTIONAL ACCESSORIES

- Bar Code Laser Scanner – Allows scan and print message retrieval

- External Light Beacon – Indicates low ink levels

- Starter Kit – Includes ink, cleaner and flush solution, printhead wipes, hand cleaner and latex gloves