Top Belt & Bottom Belt Case Taper

The operator friendly TB-2 top and bottom belt case taper is designed for large run case sealing. The top and bottom drives are ideal for tall and narrow uniform cases and heavier cases up to 85 lbs. No air is required to run the TB-2 case taping system so it can be placed anywhere in the plant.

Maximum Stability

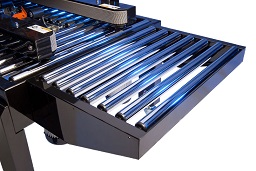

Four drive belts work in unison to move your cases consistently through for a strong and consistent seal. TB-2 utilizes a dual mast with twin lead screws for greater tape head stability and adjustable side guides to center each case. The unit also features top compression rollers to stabilize the case and push the top flaps together, making it a great solution for over-filled cases. The system is designed to keep maintenance to a minimum and provide a fast and efficient alternative to hand taping.

Flexibility For Your Operation

TB-2 offers fast and easy case changes and flexibility for boxes 5” in length and greater. Adjustments can be made on the fly with easy hand tighten knobs and cranks. TB-2 utilizes Easy-Taper Quick-Load top and bottom tape cartridges and will seal boxes as narrow as 6.0” wide and as low as 4.5” tall.

FEATURES

- Utilizes Eastey’s Easy-Taper tapehead

- Dual mast for tape head stability

- Top compression rollers

- Front and rear roller pack tables

- Plug-in and go operation

- Powder coated 12 gauge steel

- Adjustable side guides

- Industrial strength top and bottom belts

- Adjustable leg extensions

- Fast and easy box size changes

- Low maintenance

- Casters for transportation within plant

TAPING SPECIFICATIONS

- Sealer Type – Uniform top and bottom belt, top and bottom case sealer

- Machinery Makeup – Industrial strength 12 gauge steel, powdered coated for durability

- Belt Speed – 75 feet/per minute

- Tape Speed – 30 cases/per minute, depending on box size and operator efficiency

- Conveyor Height Adjustment – 24.3” to 32.3”

- Tape Size – 2” wide pressure sensitive tape, up to 15” diameter rolls, optional 3” wide tape

- Tape Cartridge – Proven design requires no lubrication, tips back for simple tape threading, removable for maintenance and interchangeable with top or bottom cartridges

- Air Requirements – None

- Electrical Requirements – 110 VAC, 60Hz, 4.0A

- Agency Approvals – CE Certification

BOX SPECIFICATIONS

- Minimum Box Size – (Length) 5 (Width) 6″ (Depth) 4.5″

- Maximum Box Size – (Length) infinite (Width) 19.5″ (Depth) 19.5″

OPTIONAL ACCESSORIES

- 3” Tape Head – Accepts 3” wide tape rolls