Vertical Case Transport System (VCTS)

Eastey’s Vertical Case Transport System allows users to print on two sides of a case eliminating the need for pre-printed cases or expensive labeling equipment and supplies. Adjustable width settings allow users to print on cases ranging in size from 10” x 10” up to 33” x 40”.

Automatic Operation

Designed for off-line case printing, the VCTS automatically feeds blank cases through a print station that is ideal for mounting hi-resolution inkjet printers and offers the ability to print virtually anywhere on either side of the case. Open access to printheads allows for easy maintenance and quick adjustments. The VCTS also features an input hopper that can hold up to 90 flat single wall cases and can easily be reloaded by one person.

Easy to Program

The VCTS includes a programmable counter that keeps track of batch quantities, rate of operation, and elapsed run time, allowing users the ability to customize case runs. The system can be easily programmed to shut down when the maximum count is reached. The VCTS batch counter is the ideal solution for users looking to print a message on specific number of cases while eliminating the need for manual case counting.

VCTS FEATURES

- Plug-in and go operation

- Fast and easy box size changes

- Powder coated 12 gauge steel

- Low maintenance

- Industrial strength side belts

- Accommodates wide box size change

- Adjustable leg extensions

- Simple integration with ink jet printers

- Heavy duty locking casters

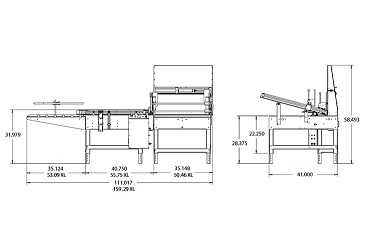

VCTS SPECIFICATIONS

- Machinery Makeup – Industrial strength 12 gauge steel, powdered coated for durability

- Belt Speed – 72 feet/per minute (approx. 50 – 10” x 10” cases/min)

- Input Hopper – Capacity of up to 90 flat single wall cases

- Input Hopper Adjustments – 10” to 33” width, no tools required

- Minimum Box Size – 10.0”

- Maximum Box Size – 33.0”

- Programmable Counter – Designed for batch operations, rate metering, and elapsed counting

- Printing System Compatibility – Designed for ink jet printing system compatibility

- Casters – Attached to each section for transport throughout the plant

- Electrical Requirements – 110 VAC, 60Hz, 4.0A

- Air Requirements – 80 PSI, 1/4” NPT Fitting

OPTIONAL ACCESSORIES

- Inkjet Printing System – Hi-resolution printing system capable of printing bar codes, graphics and text4