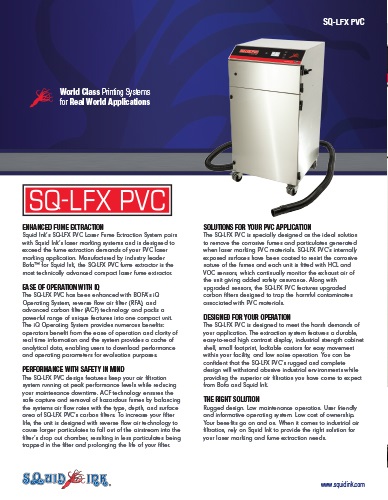

The SQ-LFX PVC Laser Fume Extraction System

Squid Ink’s SQ-LFX PVC Laser Fume Extraction System pairs with Squid Ink’s laser marking systems and is designed to exceed the fume extraction demands of your PVC laser marking application. Manufactured by industry leader Bofa™ for Squid Ink, the SQ-LFX PVC fume extractor is the most technically advanced compact laser fume extractor.

Ease of Operation with IQ

The SQ-LFX PVC has been enhanced with BOFA’s iQ Operating System, reverse flow air filter (RFA), and advanced carbon filter (ACF) technology and packs a powerful range of unique features into one compact unit. The iQ Operating System provides numerous benefits: operators benefit from the ease of operation and clarity of real time information and the system provides a cache of analytical data, enabling users to download performance and operating parameters for evaluation purposes.

Solutions For Your PVC Application

The SQ-LFX PVC is specially designed as the ideal solution to remove the corrosive fumes and particulates generated when laser marking PVC materials. SQ-LFX PVC’s internally exposed surfaces have been coated to resist the corrosive nature of the fumes and each unit is fitted with HCL and VOC sensors, which continually monitor the exhaust air of the unit giving added safety assurance. Along with upgraded sensors, the SQ-LFX PVC features upgraded carbon filters designed to trap the harmful contaminates associated with PVC materials

FEATURES OF THE SQ-LFX PVC

- iQ Operating System

- Automatic Flow Controler

- Turbine with high airflow and pressure

- Reverse Flow Air filter technology (RFA)

- Auto sensing voltage (90-257v) – For global use

- HCL and VOC gas sensors

- Easi-Seal filter location mechanism

- High contrast display

- Real time airflow reading

- Advanced Carbon Filter technology (ACF)

- Filter status warnings

- Independent filter condition monitoring

- Run safe (filters must be installed correctly for the unit to operate)

- Low noise levels

- Lockable castors

- Remote diagnostics via USB

- Remote stop / start interface

- Filter change / System fail signal

TECHNICAL SPECIFICATIONS

- Dimensions – 43” (H) x 17” (W) x 25” (D) (1092 mm x 431 mm x 635 mm)

- Cabinet Construction – Brushed stainless steel

- Airflow / Pressure – 115v – 320m³/hr / 96mbar 230v – 350m³/hr/96mbar

- Electrical Data – 90 – 257v 1ph 50/60Hz, Full load current:12.5 amps /1.1kw

- Noise Level – < 60dBA

- Weight – 209lbs (95kg)

- Approvals – CE, UL

PRE FILTER SPECIFICATIONS

- Surface Media Area Approximately – 2m²

- Filter Media – Polyester

- Filter Media Construction – 8 Pocket Bag Filter

- Filter Housing – Corrosion Resistant Coated Stainless Steel

- Filter Efficiency – F8 (95% @ 0.9 microns)

COMBINED FILTER SPECIFICATIONS

- HEPA Filter Media – Glass Fibre

- HEPA Media Construction – Maxi Pleat With Webbing Spacers

- Treated Activated Carbon – Blend of impregnated activated carbons (21kg)

- Filter Housing – Corrosion Resistant Coated Stainless Steel

- Filter Efficiency – 99.997% @ 0.3 microns